|

|

Back in the fall of 2008, this DIY aquarium background project marked the

beginning of a new hobby interest for this website author. The new background

also breathed new life into what was previously little more than an average,

uninspired, 55 gallon aquarium.

It was the first of what would become many DIY backgrounds over the next few years and a key motivation behind the creation of the Dramatic AquaScapes website.

It was the first of what would become many DIY backgrounds over the next few years and a key motivation behind the creation of the Dramatic AquaScapes website.

DIY Aquarium Background

Submersed Tree

and Rocks

Submersed Tree

and Rocks

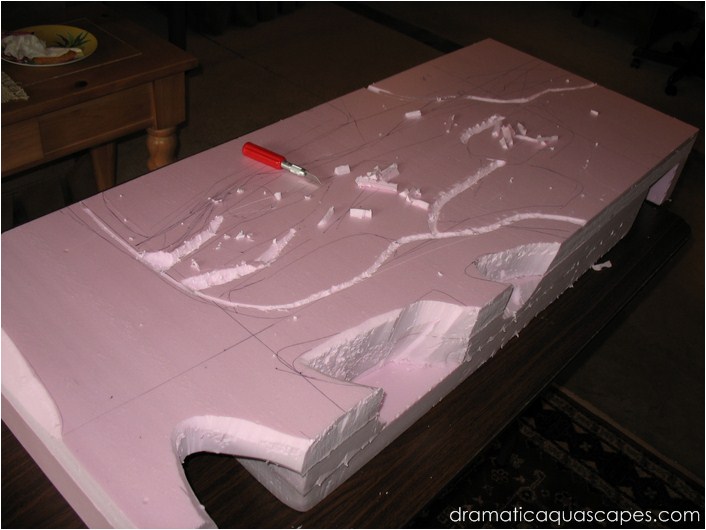

This design began with three layers of 1½" thick

polystyrene sheet from Home Depot. The 4'

wide sheets were cut to 18" tall then glued

together using a caulking gun and GE brand

Silicone #1. The #2 version of their silicone

product contains mold inhibitors which are good

for your house, but would be bad for your

aquatic life.

The tree and rocks pattern was rough sketched in ink pen. the first cuts were with an exacto knife.

The tree and rocks pattern was rough sketched in ink pen. the first cuts were with an exacto knife.

A cordless drill with wood bit was then used to

make quick work of digging out the deeper

recesses around the tree and rocks. The small

red handled tool in the photo is a rasping tool

usually intended for use with wood, but it also

works very well for smoothing rough edges in

the polystyrene.

While both of these tools can produce the desired results, they can make a pretty big mess so having a shop vac handy or at least broom is recommended.

While both of these tools can produce the desired results, they can make a pretty big mess so having a shop vac handy or at least broom is recommended.

At one point, it made sense to separate the

background into three large sections. This

made it easier to cut out paths around and

behind the rock formations for fish to hide and

play. Having three smaller sections instead of

one large section was also necessary to

install the background due to the center brace

on top of the aquarium.

A folding table in the garage covered with plastic trash bags made a good work area.

The first layer of Quikrete Quikwall brand cement was mixed to a latex paint-like consistency and applied with a disposable paint brush. This was the first of a total of three layers of cement to be applied.

A folding table in the garage covered with plastic trash bags made a good work area.

The first layer of Quikrete Quikwall brand cement was mixed to a latex paint-like consistency and applied with a disposable paint brush. This was the first of a total of three layers of cement to be applied.

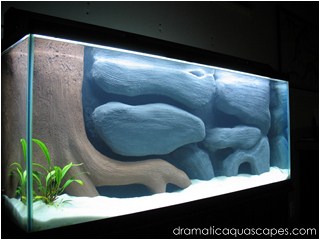

This photo shows the completed sections each

with three layers of cement applied. Quikrete

brand brown and charcoal liquid color were

added to the cement mix before brushing on the

final layer.

Before the Quikrete liquid acrylic became part

of the build process, the cement had to be kept

moist while curing. Another way I've learned to

do this if you want to avoid the extra cost of the

liquid acrylic is to moisten the curing cement

then wrap in plastic. Liquid acrylic is still

recommended though for the overall long term

strength of the background.

Page 1 of 2